MES system

MES system

1, System Overview:

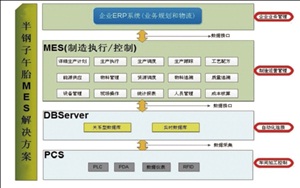

China's automobile industry has entered a rapid development period. In recent years, China's automotive industry has gained rapid development, vehicle production has increased annually, escalating product quality, product structure has also changed. High-end cars need high-quality tires matching, which is a prerequisite for the radial tire market to mature. But how to achieve real-time monitoring of tire production and quality management, traceability is a challenge for manufacturers and problems, the traditional manual records barcode retrospective statistics, time-consuming, inevitable human typographical error, entry missing difficult in the production, quality, delivery, after-sales and other business related and applied to a large number of bar code information can not be achieved products, raw materials, production machine, the operator of the lateral and longitudinal retrospective query, and this huge production of tires operability is not strong production industry.

MES system can maximize the realization of the seamless integration and ERP systems, sharing fundamental data with the ERP system and other business data, sales, production, inventory, quality of retrospective integration from the front-end sales orders, production tasks to the MES system single in the whole process of monitoring and management of the production process monitoring, detection and back-end storage to maximize the production efficiency of customs and production quality clearance, corporate planning, human resources, production equipment, unified management and control capacity the best optimization. The use of bar code and RFID can be further refined, precise management of the plant energy-saving, emission reduction, incremental, high-quality production!

2, management objectives:

? production tasks scheduling and sub-single

◆ Sales Order

MES system is automatically collected ERP system sales orders, save for the the MES system's internal data, based on basic data as the next step in the production task scheduling and single operation.

◆ MRP arithmetic (Material Requirements Planning, MRP)

Is based on sales orders and forecasts single-accordance with MRP balanced formula for computing

The SRP (Sales Requirement Planning) production (generated by the sales order)

The SRP production projected gross demand for materials in accordance with the bill of material recorded on the use of the number, and then consider the existing amount of reservation amount, net count in the share amount, automatic calculation of supply (procurement, homemade and outsourcing) number and date, as requisitions, orders for procurement, production orders and outsourcing plan is based. SRP is a plug-in production mode.

◆ Manufacturing Order Production Scheduling

ERP system sales orders collected according to the MES system, group leaders selected sales orders, generate production task list, production scheduling, select the appropriate production task list, MES system based on the currently selected production task list automatically based on the device information, team information, information, materials, single-generated production tasks were distributed to each of the production equipment. The production of the the SRP production and SRP (Sales Requirement Planning) according to the selected sales order.

◆ production schedule management

Workshop for the completion of the production plan, the workshop production schedule to determine when, where and what kind of job. And specify the number of production and the date of completion of the various stages of production. Then workshop production schedule jobs, control and production records to ensure balanced production, leveling.

◆ production tasks scheduling single

MES system, the production of the various sub-single final correspond to each specific production equipment and personnel, the single may not go to work because of the machine equipment failure or production personnel, and other causes can not be produced, then you need to production scheduling to re- production task scheduling, scheduling production tasks on this device corresponding to the other machine equipment and personnel for production, in order to ensure that the entire production task total production of the single-task completion.

? Product retrospectively goals

(1) Product material traceability; product barcode number, you can query to the quantity, weight or length of the raw materials used, the use of the tree structure dates back to the top, step by step, to eliminate the black hole of management and traceability.

(2) process, the operator retrospective; RFID encoding on the production task list, product barcode or production equipment, the query through the production process, processing team, the operator.

(3) the production task list, the working hours of the product traceability; production task list or product bar code, the query of labor, abnormal working hours;

(4) the production task list, product defect rate, the overall production efficiency;

(5) production equipment retrospective: single number query the historical production machine device information;

(6) The workers in accordance with the time period, retroactive participation in the operation of the production task list, products and processes, working hours.

(7) materials, components transverse retrospective; query a batch materials, semi-finished products are used in which production task list, products.

? To site management objectives

(1) shows the current total production task orders, production task of the single production status

(2) data validation on RFID read head device according to the RFID number on the carrier material equipment and production equipment, raw materials production site matching check, eliminate production errors picking and a long time to find material preparation;

(3) real-time display of the current production equipment, machine status information: statistical failure rate of equipment, production efficiency

(4) real-time display of the current production personnel data, statistical production performance data;

(5) whole plant material chase, real-time recording and collection of data for all aspects of production, such as length, weight, width, thickness.

.jpg)

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Hotline:400-818-6918

Hotline:400-818-6918

Web:m.efuo.cn

Web:m.efuo.cn